GLASS INSULATORS

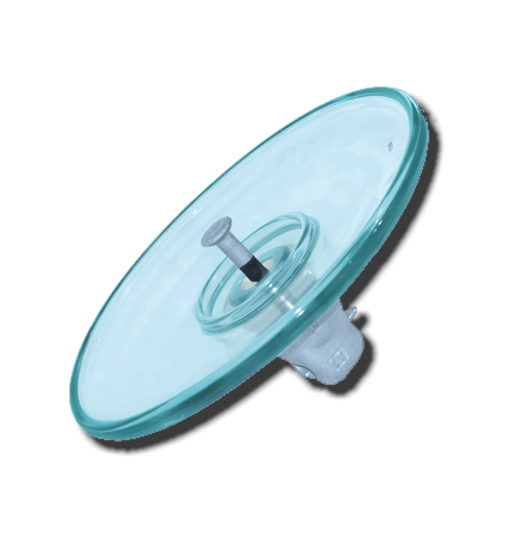

TOUGHENED GLASS DISC INSULATORS TEXPI/SYGG

TOUGHENED GLASS DISC INSULATORS TEXPI/SYGG

TOUGHENED GLASS DISC INSULATORS TEXPI/SYGG

As soon as electrical energy could be generated in large quantities, its use required adequate means to transmit that energy. Developing a component that isolates the live conductor was the main initial challenge. Although almost any solid non-conductive material in a dry environment can insulate several hundred or a few thousand volts, it was soon realized that it was difficult to design an effective insulator for use in humid and polluted environments.

The first insulators for electricity distribution networks developed in the 1880’s were based on the designs of insulators used in telegraph lines, using porcelain and annealed glass as raw materials. As stable insulating materials, very resistant to corrosion/deterioration, mechanically suited to application stresses, plentiful and cost-competitive, use quickly spread, becoming the most widely used insulating materials for electrical equipment and insulators.

It was only in 1935 that the Pilkington Company, UK, introduced the toughened glass disc insulators to the market, with an important advantage: In the event of an electrical or mechanical failure, the dielectric completely self-destructs, making the failure easy to see for maintenance teams.

Although the cost of toughened disc insulators is a small percentage of the cost of building a substation, transmission line or electrical installation, the failure of this component can result in serious problems, such as accidents and prolonged shutdowns, with important economic and social consequences.

At first glance, toughened glass insulators appear to be simple devices. They are, however, high-tech components: Decades of study, testing, compositional development and manufacturing refinement were required to achieve the exceptionally high level of reliability that high-quality toughened glass insulators can provide. For example, the spontaneous breakage rate of correctly sized high quality toughened glass disc insulators is less than one unit per 10,000 installed per year.

We at TEXPI Equipamentos have been supplying high quality toughened glass insulators for more than 10 years for the most important substations, energy works and transmission lines in Brazil and the world with excellent history of performance, reliability, durability and after-sales service. Make your inquiry with us! We work with all technologies in insulators: glazed porcelain, toughened glass and composites (HTV silicone rubber with fiberglass core). We are committed to serving our customers with excellence.